Custom Converting Services

converting Services for custom Closure & attachment Solutions

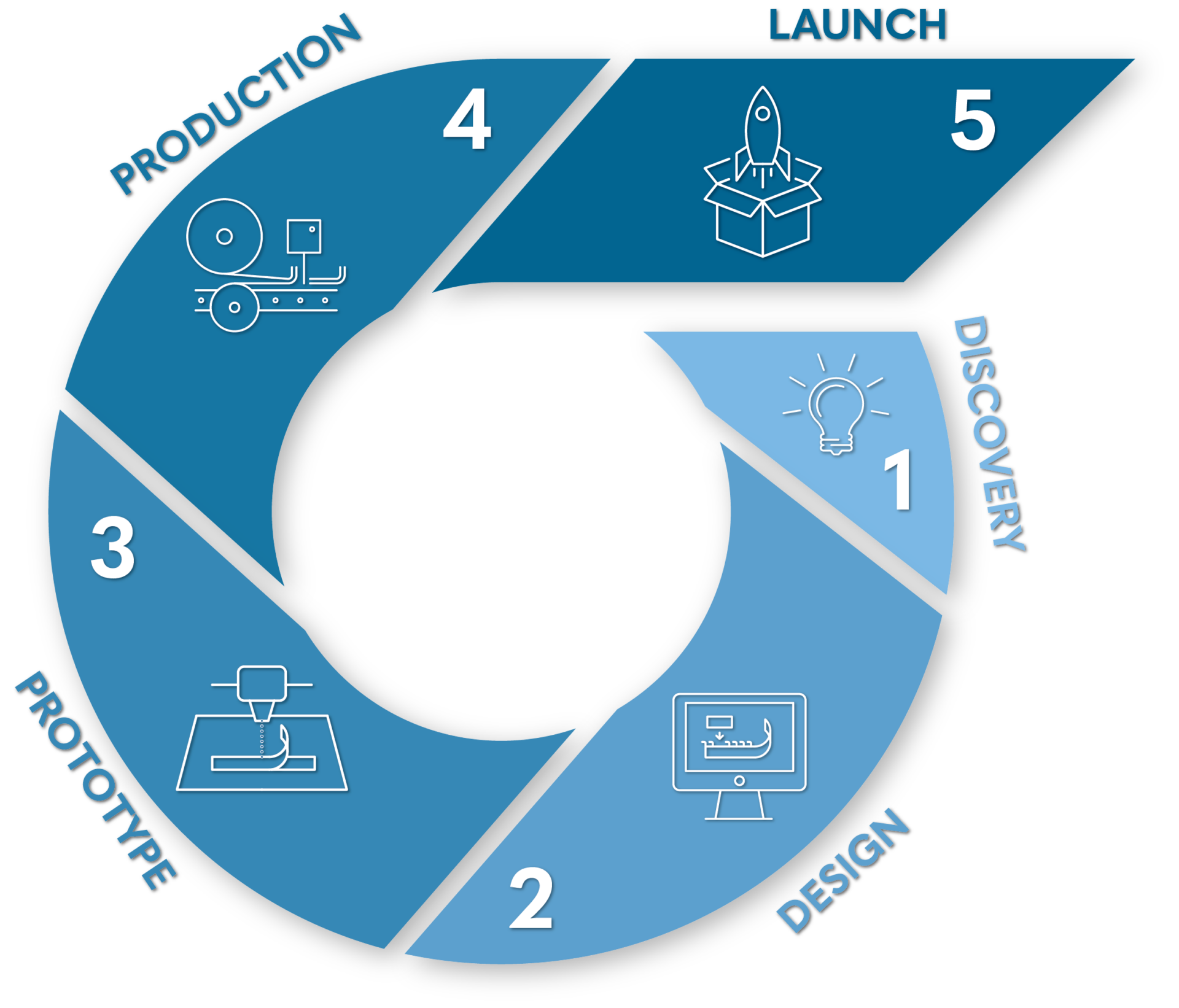

Halco specializes in custom converting services, offering comprehensive solutions for OEM manufacturers and their tier suppliers to enhance design and assembly. The wheel on the right represents our customer’s journey in designing, manufacturing, and launching a new product. It also describes how we work with our customers to provide customized hook & loop fastening solutions.

Click on each step of the wheel, 1 through 5, or expand the sections below, to learn more about how we help our customers manufacture the best and most innovative closure and attachment systems.

Learn More about our converting capabilities

Click on any of the steps below to read more about our services to our customers in each step of the product development cycle. Many of the details of our converting capabilities are located in Production, but we encourage you to involve us early in Discovery and Design and to explore each step. You can follow the hyperlinks to learn more about the details of a particular service.

Discovery

In the Discovery stage of product development, Halco has extensive expertise in hook and loop fastening solutions, adhesives, converting and fastening parts fabrication. We encourage you to involve Halco early when exploring fastening concepts so that Halco can help you identify new specialty materials, product features and manufacturing capabilities.

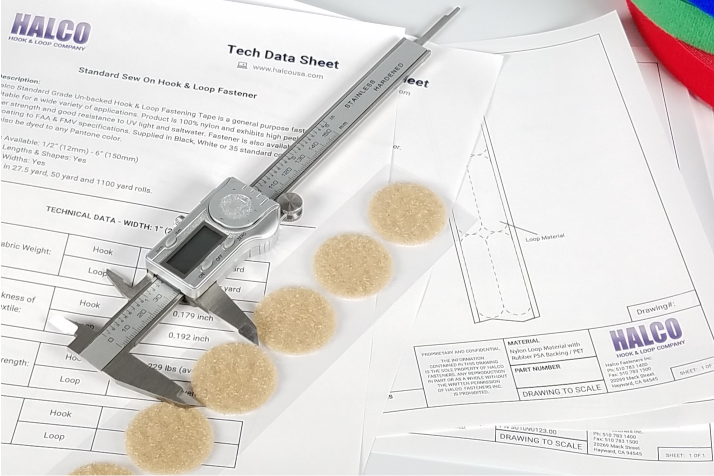

Design

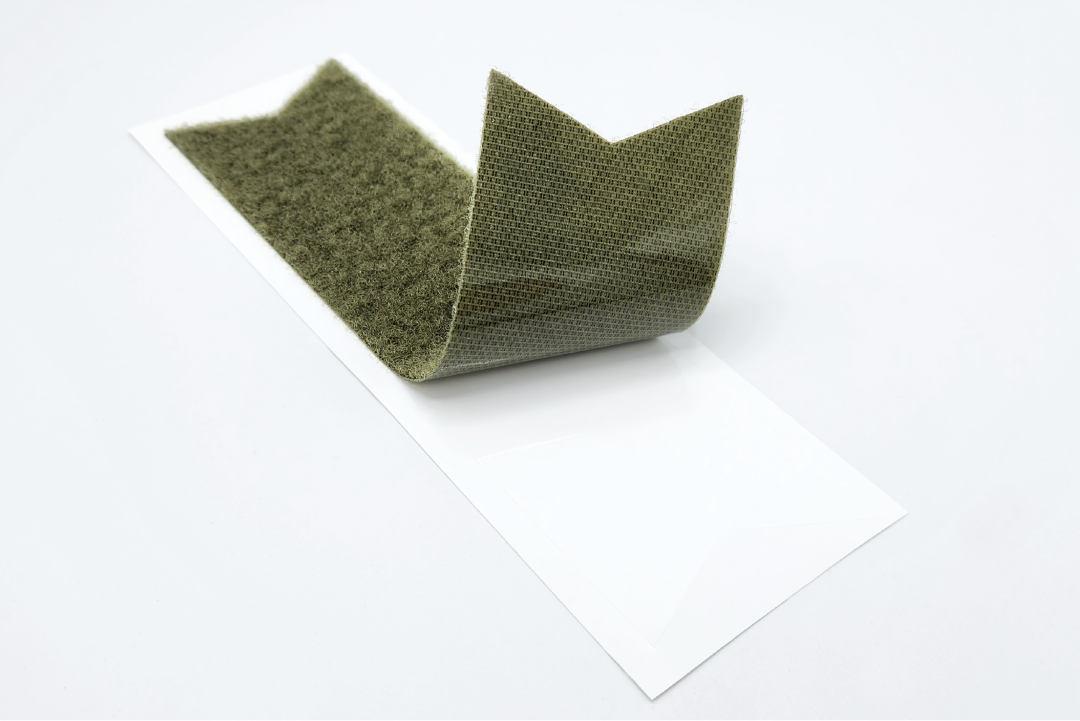

Halco’s application engineering support plays a crucial role in transforming product concepts into optimized fastening solutions. With specialized knowledge in fastener design, we provide assistance with engineering drawings, offer a unique dye-to-match color program and do custom logo imprinting to meet your functional and aesthetic design requirements. Whatever your design needs, Halco can help!

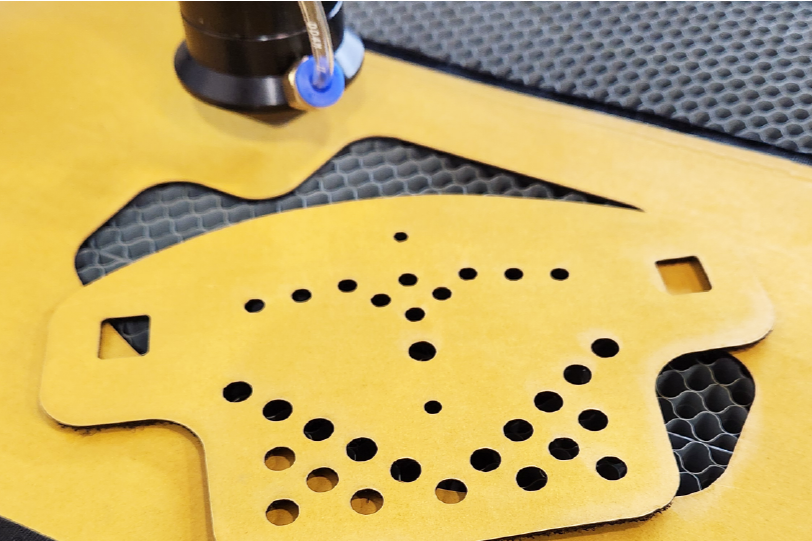

Prototype

Halco accelerates product development by rapidly creating prototypes that integrate customer needs, market insights, and sustainability goals. By utilizing advanced manufacturing capabilities such as laser cutting and custom adhesives, Halco ensures that each prototype meets all key specifications so that new iterations can rapidly be produced and reviewed.

Production

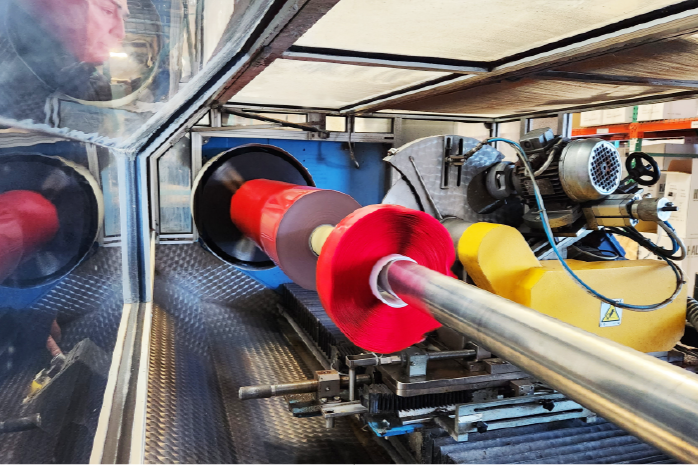

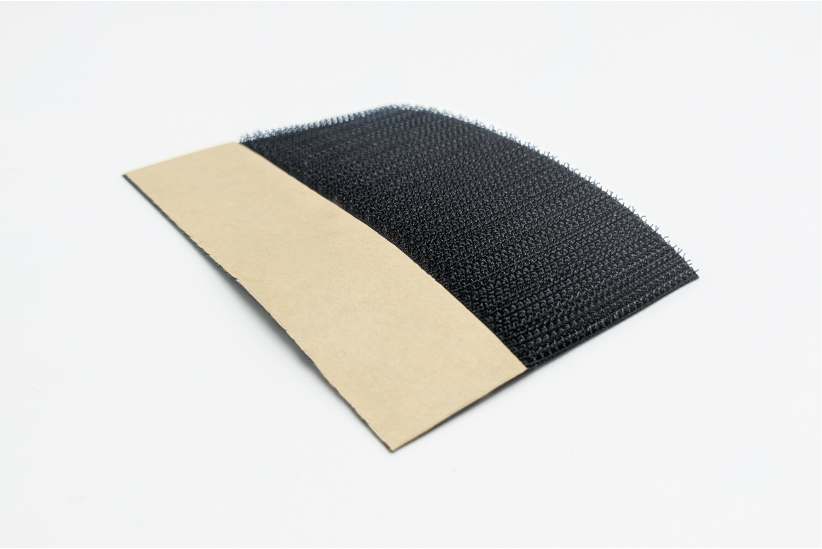

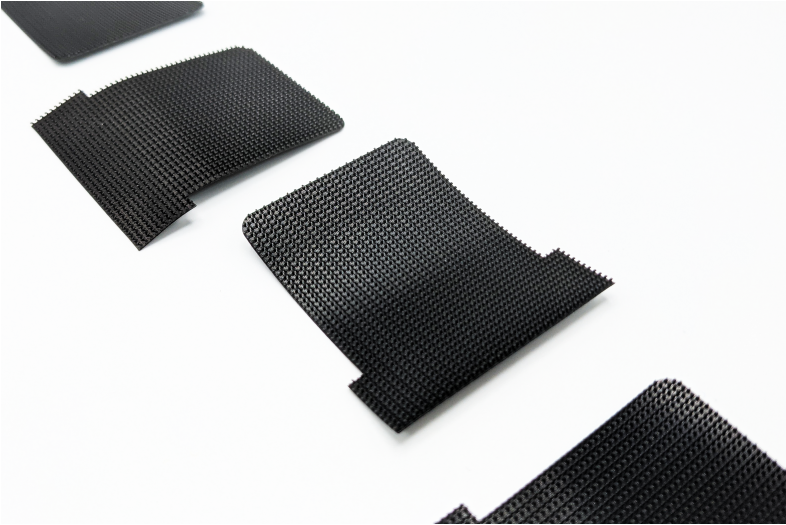

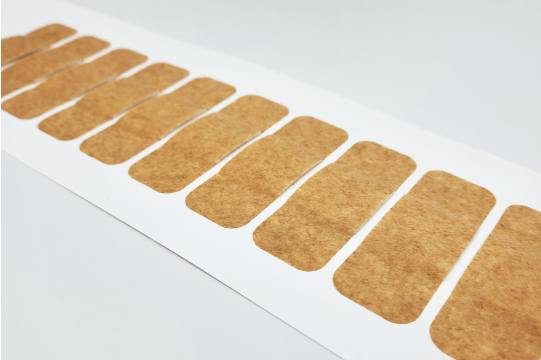

Halco’s comprehensive production capabilities are tailored to meet the precise and diverse needs of manufacturers. These services range from basic strip cutting, to custom adhesive lamination and die-cutting to the fabrication of more advanced multilayer laminates, straps and fastening parts.

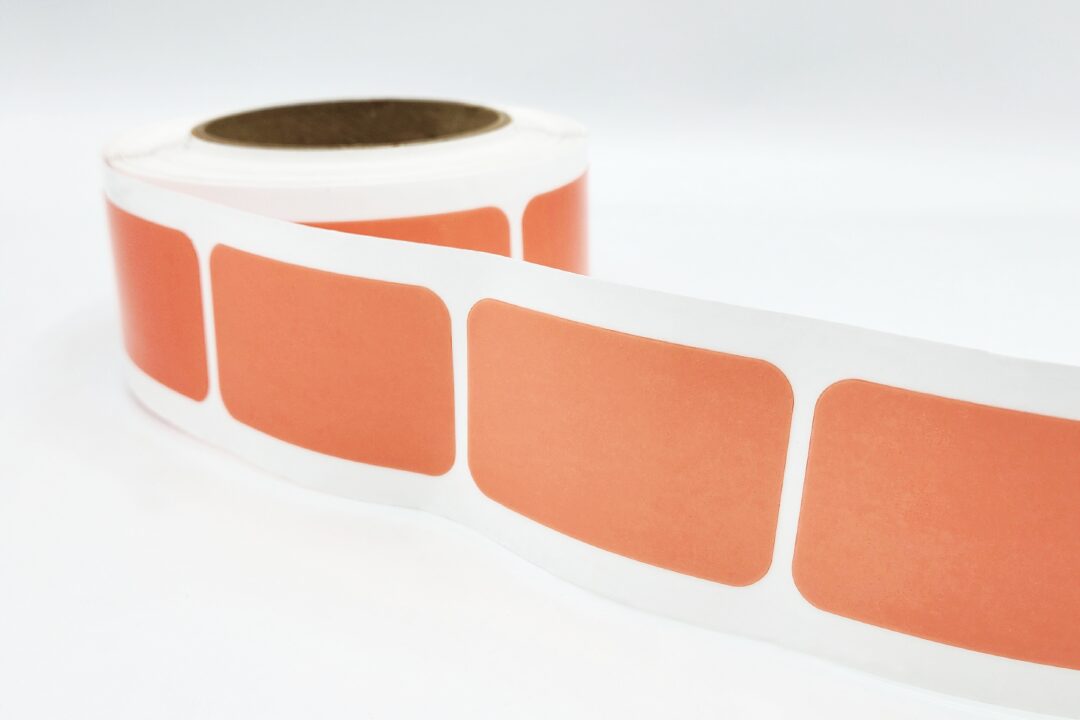

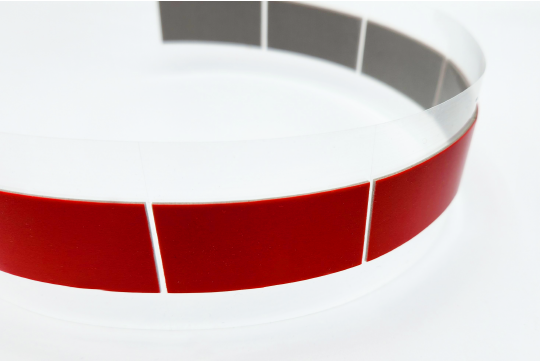

Custom laminated Adhesives

Halco offers comprehensive adhesive tape converting services and is a 3M Preferred Converter. Services include corona treating, adhesive tape lamination and tape converting and die-cutting.

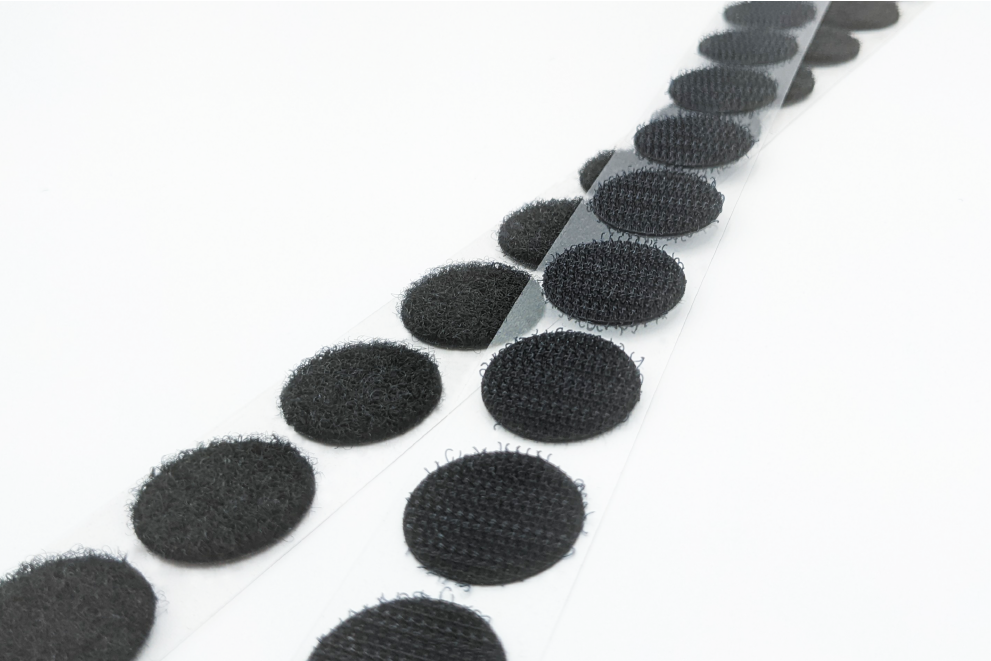

Slitting & cutting services

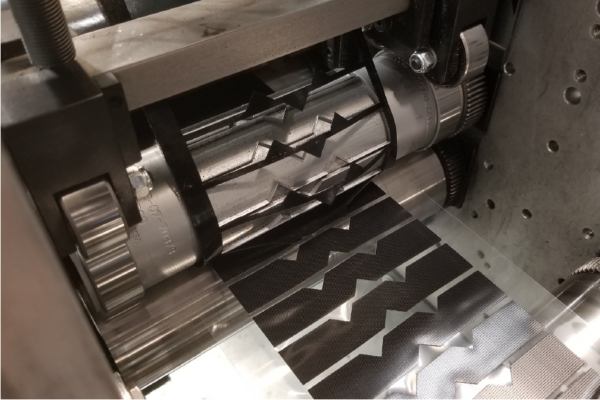

Halco provides comprehensive services related to slitting, strip cutting, perforating, die-cutting and edge processing for Halco’s hook and loop materials, Dual Lock, adhesive tapes and related materials. Die-cutting capabilities include wide format laser cutting, steel rule press die-cutting and high-speed rotary die-cutting.

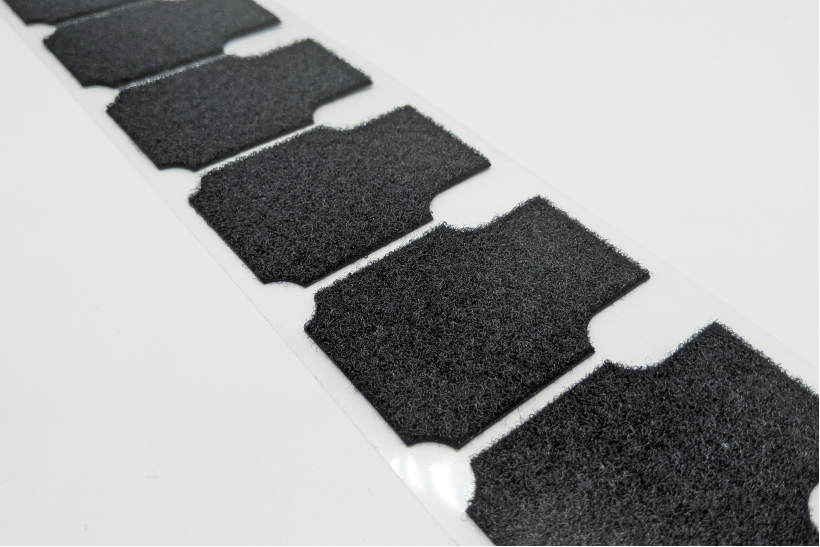

long length rolls, winding services & Liners

Halco helps improve manufacturing productivity by providing long length rolls, spool wound rolls and relinering services to reduce changeovers and better match the manufacturing processes of its customers.

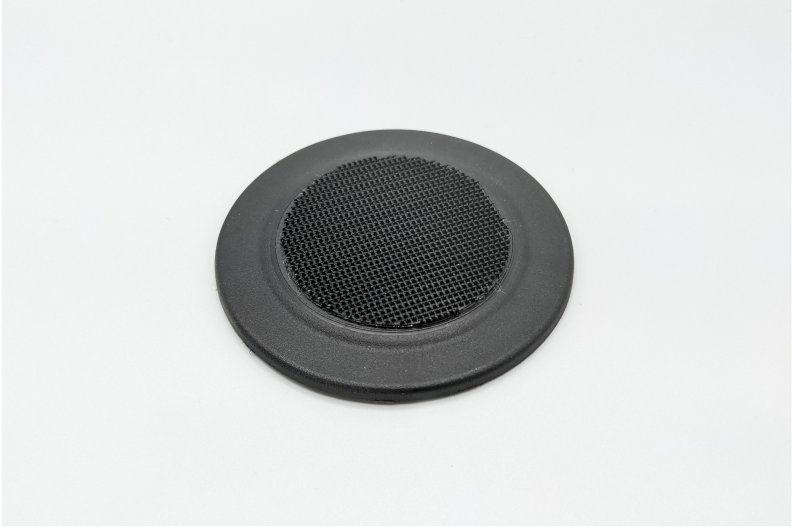

Stitching, Welding and Parts Fabrication

Manufacturers often ask Halco to provide basic fabrication capabilities such was stitching, welding and laminating two or more materials. These services are often performed in combination with die-cutting and hardware to produce hook and loop fastener assemblies.

LAUNCH

Halco provides superior service in support of its products and its customers, including quality assurance, custom packaging, delivery and inventory management.

Custom CONVERTED Parts

Tell Us About Your project!

Do you have a project that needs some converting support? Can we customize a hook and loop or Dual Lock fastening component for you?

Product Certifications

Halco partners with world-renowned external laboratories to ensure that material and design specifications are met.

Specification Examples:

- MIL SPEC A-A-55126B

- FMVSS302

- GM W15015 (Flammability, Natural Weathering)

- GM 3618M

- FORD WSS-M15P32-D

- FORD WSB-M15 P35-A3

- DAIMLER CHRYSLER PF-8543

- FCA US Material Standard – MS-JE-9-9

- EO Sterilization

- CAL TB 117

- FAR 25.853 – 12 Second Vertical

- UL 94 Vertical Burn

- REACH / ROHS

- CALIFORNIA PROP 65

- OEKO-TEX

- NFPA 2112

- ISO 10993-5 Cytotoxicity (Biocompatibility)

HALCO is certified to ISO 9001 (2015) and ISO 13485 (2016)

Learn more about our commitment to quality. LEARN MORE >