Slitting, Strip cutting and die-cutting

Halco offers comprehensive services for slitting, strip cutting and advanced die-cutting. This includes edge processing. Whatever format you need to speed your assembly, Halco’s unmatched slitting, cutting and converting services lead the way.

Knife Slitting and Edge Processing

These processes ensure the material is exactly the width that customers need and that the edge of the material fits your process. Halco uses knife slitting to slit its fastening materials down to very narrow widths and can provide the material with a selvedge edge or without. Many of our customers also like Halco to make a roll with a skived finger lift edge. Wider width materials and adhesive tapes are slit to size on our lathe slitter.

Benefits:

– Precision cutting for exact material width

– Improved material handling

Service Options & Features:

– Long length, narrow-width slitting available

– Selvedge or skived finger lift edges available

Applications:

– Automotive upholstery

– Insulation and sound damping

– Mats, rugs and carpets

– Industrial sewing

Strip Cutting

Enhance productivity with Halco’s strip cutting services, which provide pre-cut hook and loop materials in prescribed lengths. Our strip cutting services are designed to fit seamlessly into your production process, reducing handling time and increasing efficiency. Individual pieces, kiss-cut strips and perforated pieces on a roll are available.

Benefits:

– Increased production speed

– Reduced handling time

– Less need for cutting tools and equipment

Service Options & Features:

– Individual pieces, perforated or kiss-cut on a roll

– Mated or unmated sets

Applications:

– Retail packaging

– Display and graphic products

– Consumer goods

– Medical devices and components

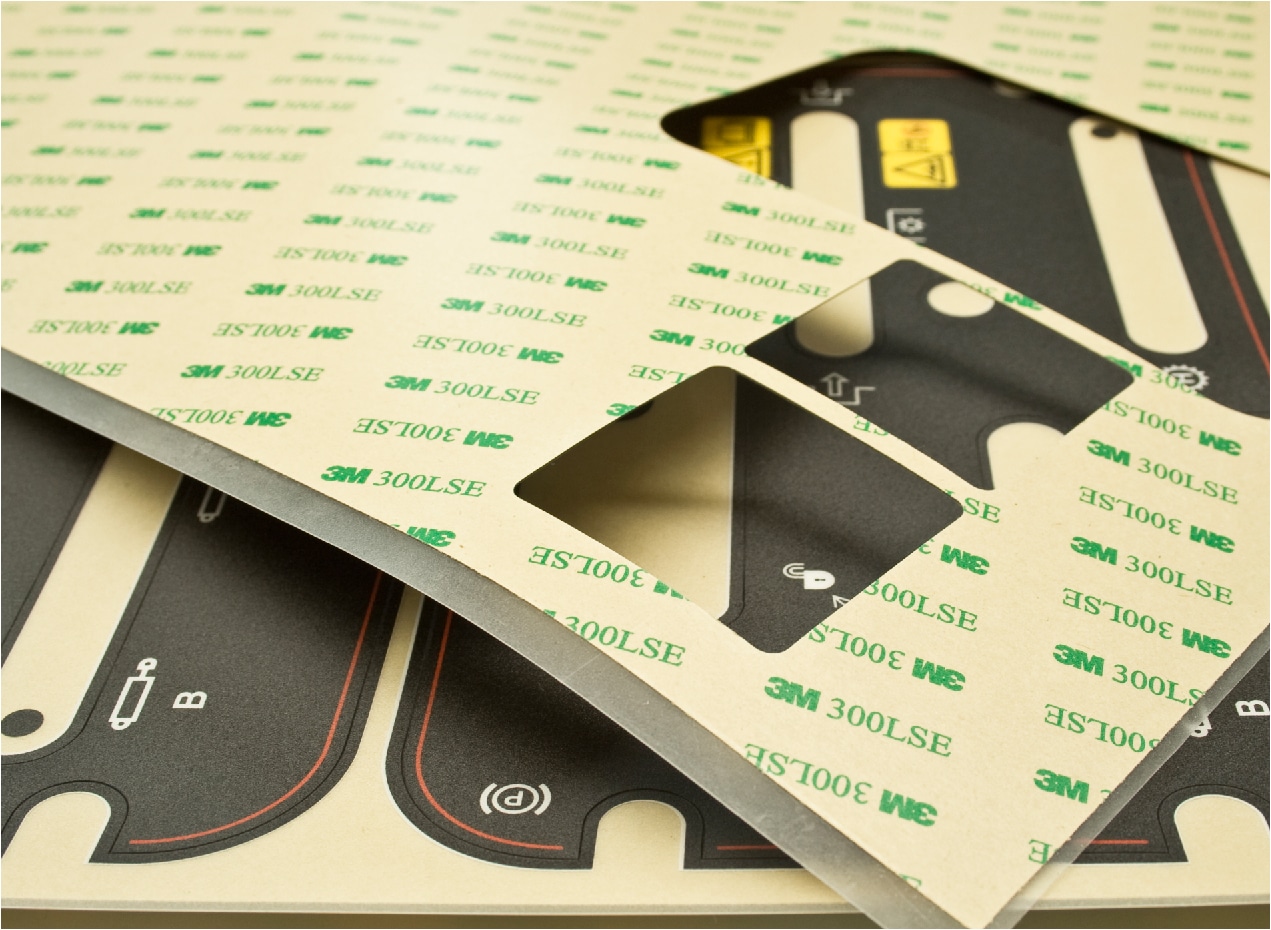

Steel Rule Die-Cutting

Our steel rule die-cutting services provide unmatched versatility for producing intricate and complex hook and loop shapes. This process is ideal for prototyping and low-to-medium run lengths, ensuring precise and economical fabrication.

Benefits:

– Precision cutting for optimal designs

– Cost effective tool production for short run production

Service Options & Features:

– Heavy-duty flatbed presses and steel rule die

– Capable of cutting thick hook and loop laminates

Applications:

– Custom fastener prototypes

– Packaging components

– Complex multi-layer laminates

– Specialty products

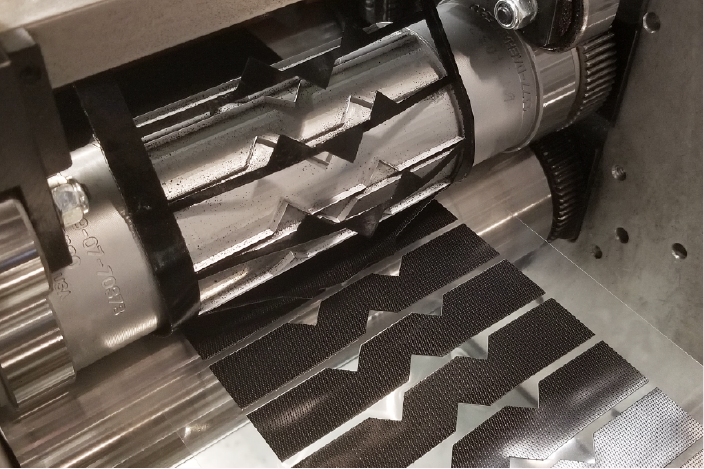

Rotary Die-cutting

Halco’s advanced rotary die-cutting technology is designed for high-speed, continuous production of precisely cut hook and loop components. This method is ideal for high-volume applications, providing tight tolerance processing and excellent registration.

Benefits:

– High-speed, continuous production

– Dimensionally accurate parts

Service Options & Features:

– Cylindrical dies for efficient handling of long runs

– Ideal for kiss-cutting, fabric webs, and continuous perforated strips

Applications:

– Strap fabrication

– Hook and loop cable ties

– Medical devices

– Military and defense products, helmets

Wide Format Laser Cutting

Our latest addition, a large format laser cutter, enhances our ability to deliver precise and efficient die-cutting services for a wide range of hook and loop materials. This cutting-edge equipment allows us to offer rapid prototyping and large-scale production with unparalleled accuracy, ensuring your products meet the highest standards.

Benefits:

– Faster time to market

– Enhanced design flexibility

Service Options & Features:

– Vacuum assisted cutting

– No need for traditional dies

– Versatile material handling

Applications:

– Strap fabrication

– Automotive & aerospace die-cuts

– Medical & emergency response

– Military, defense & first responder

Tell US About Your Slitting & Die-Cut Needs

We’d love to know more about a project or fastener prototype need you might have. We offer free samples for evaluation, will help with drawings and specs and can turn around a prototype often within a few days.

Start Your Custom Fastener Project Today!

Partner with Halco for your custom fastener needs. Contact us today to start your journey from concept to production with our expert team.