Halco is a uniquely qualified supplier of automotive hook and loop fastening parts and materials to automotive OEMs and their tier suppliers. Unlike other fastening suppliers that focus on volume production, Halco provides engineering support during the design and prototyping stage, often doing small prototype runs, thus helping its automotive customers develop unique fastening solutions that enhance product design and speed productivity. Many of the automotive hook and loop fasteners that Halco provides the industry are used in automotive interiors.

There are a variety of reasons why Halco brings unique value to the automotive industry and why it’s a good choice as a partner for the development of fastening and attachment systems.

Halco Has a Deep Portfolio of Automotive Specialty Hook and Loop Fasteners

Many fastening applications in the automotive interiors market require specialty hook and loop fasteners that are unique to that specific application. For example, vehicle seating manufacturers require hook and loop fasteners, like mushroom hook, that can be effectively molded into the foam during the forming process so that the seat covers can be pulled over the foam and easily attached. Other manufacturers might need hook and loop straps that are flame-retardant. Halco is a uniquely positioned supplier as it has many of those specialty automotive hook and loop fasteners that are specified by the industry.

Halco is also an expert at converting Dual Lock for attachment applications. Dual Lock is frequently used for headliners and sunroof assembly, as well as other specialty vehicle applications. Recently, Halco converted nearly 28 miles of Dual Lock for Tesla to help resolve a recall situation.

Halco’s Products Meet Industry Standards And Are Specified by OEMs

The automotive industry is driven by a set of specifications and industry standards. As an example, General Motors recently added Halco’s back-to-back bundling tape to its GM Materials Approved Source List for hook and loop cable ties for wire harnesses and automotive hook and loop strap applications to secure accessories (GMW17585 Type 2). Other Halco hook and loop products are specified in the automotive market and meet industry standards, like the FMVSS302 standard for flammability. You can see a list of some of those standards and specifications on our Quality page.

Halco Offers Automotive Adhesive Choices Approved by the Industry

Many of the substrates used in automotive interiors are difficult for adhesives. These include painted metal, rigid plastics, thermoformed rubber, foams, and textiles. It’s important that any adhesives that are proven to adhere well to these substrates, don’t require priming and also don’t outgas in the cabin interior. Halco offers a range of adhesive options that can be custom laminated to most Halco hook and loop materials that are already proven and accepted by industry.

Halco Offers Unique Environmentally Responsible Solutions

The use of environmentally responsible materials in vehicles is quite an important and increasingly important factor in the selection of materials for automotive interiors. Recently Halco introduced its ReVive Recycled Hook and Loop product line line made from 100% recovered ocean plastics. This new product line is suitable for sewing or can be laminated with an automotive adhesive. Halco also offers pressure-sensitive adhesive choices that are made without the use of solvents.

Halco Converts Materials to the Ideal Format to Simplify and Accelerate Assembly

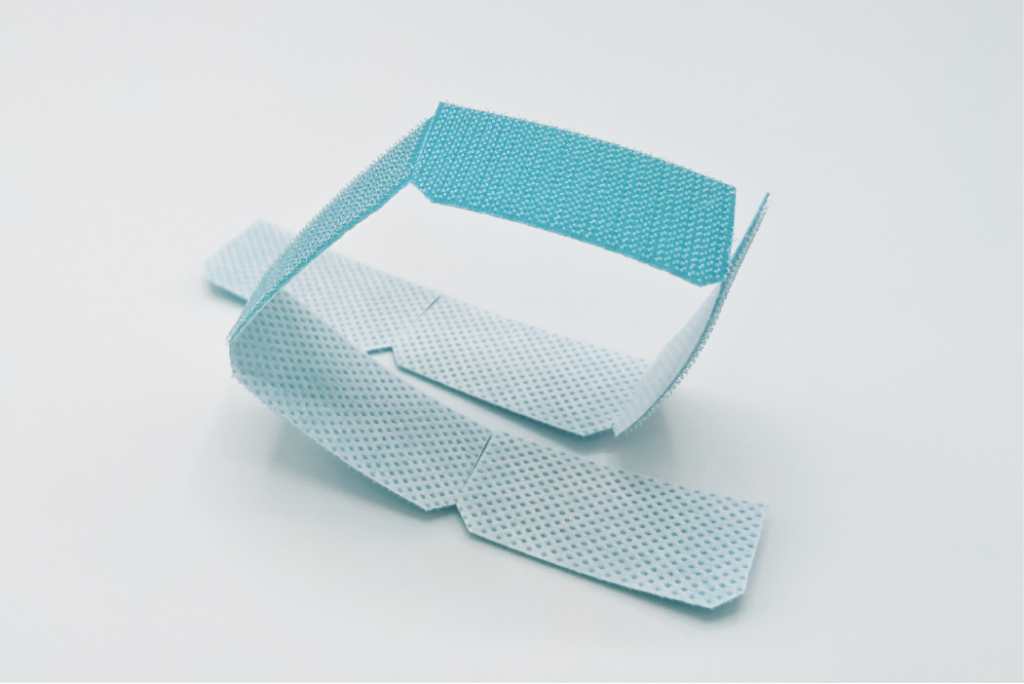

Sometimes the magic is not in the hook and loop fastening material itself, but in how the material is prepared and converted to make it easier to use in assembly. Halco helps eliminate the need for cutting on the production floor by perforating hook and loop parts on a roll. Or, if the part is adhesive-backed, Halco can kiss cut the part down to the liner so that each individual part is easy to pull off the roll, instead of fishing for a part in a box or bag, and then trying to remove the liner.

And Halco often fabricates more complex hook and loop parts and assemblies for its customers. We die-cut parts, custom laminate adhesives, sew, weld, print and even integrate to plastic components so that it meets to the design requirements of the customer. Whatever your reclosable fastening needs, Halco can build it.

The Expertise and Responsiveness Of Our People

Halco does bring a lot of product breadth and capability, but the most important reason to work with Halco on a fastening or attachment solution is the knowledge, expertise and willingness of our people to assist our customers. In fact, we’re known for it and it’s what we do every day. And this is further proven by our ability to work with engineering drawings, produce prototypes quickly, and do small production runs. When you need an answer or need something done, we make it happen. If you’re looking for a company to be your partner in fastening and attachment applications, Halco is your best choice.

You can learn more about our products and participation in automotive applications here. You can also request a sample of Halco products for your automotive project below:

Request A Sample

Tell us a little about your project and material needs so we can be of assistance.