At Halco, we are committed to advancing our capabilities to better serve our customers in the aerospace, automotive, defense, medical, industrial, and display and graphics sectors. As part of this commitment, we are excited to announce the installation of a state-of-the-art large format laser cutter at our Hayward, CA facility. This cutting-edge equipment is already transforming how we deliver precise, high-quality die-cut parts and prototypes for our valued partners.

Unmatched Precision and Speed with Laser Cutting Technology

The introduction of our large format laser cutter marks a significant milestone in our ongoing efforts to enhance our converting services. This advanced machine is designed to deliver two key benefits that will streamline your product development process:

- Rapid Prototyping Without Traditional Dies:

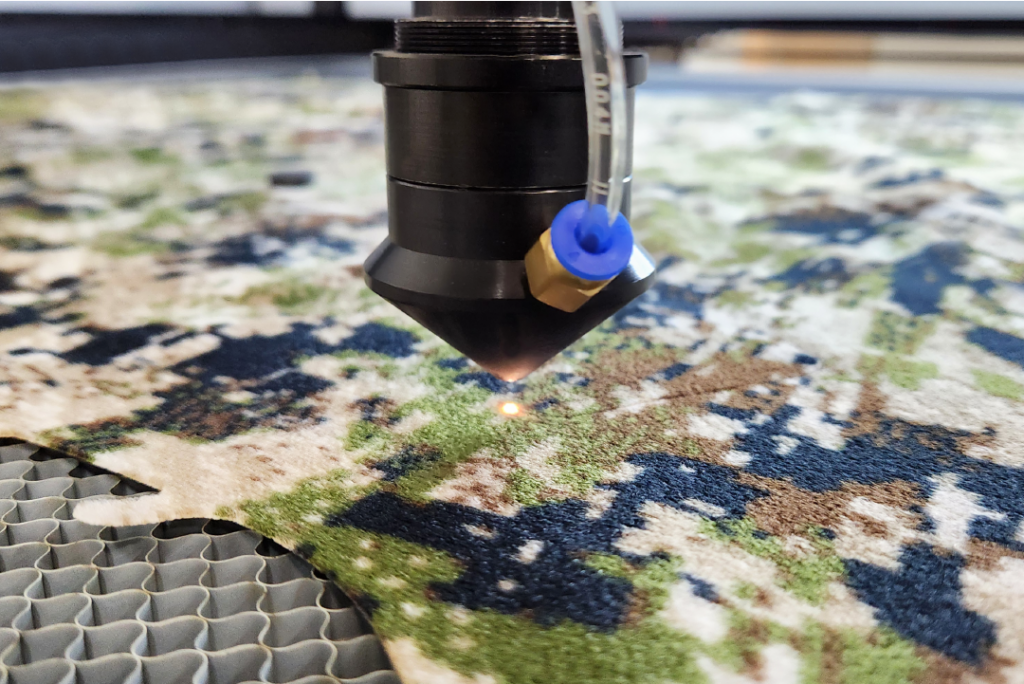

Gone are the days when creating a die-cut prototype meant waiting for a die to be made for either a rotary or steel rule press. Our new laser cutter can produce prototypes quickly and efficiently, allowing for rapid iterations during the design and development stages. This speed enables your team to move forward with confidence, knowing that precise, functional prototypes are available on-demand.

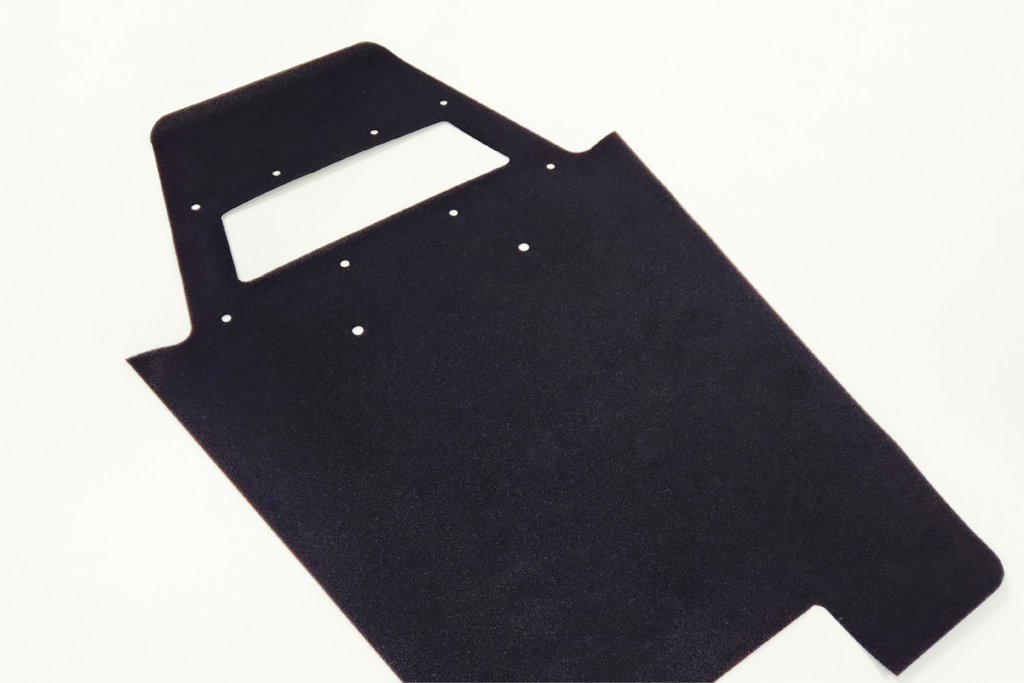

- Capability to Handle Large Format Die-Cuts:

Traditional rotary presses are often limited in the size of die-cuts they can produce. Our large format laser cutter, however, can handle sizes that were previously unattainable, giving you greater flexibility in your design process. Whether you need large parts or intricate designs, our laser cutter delivers superior results with the highest level of accuracy.

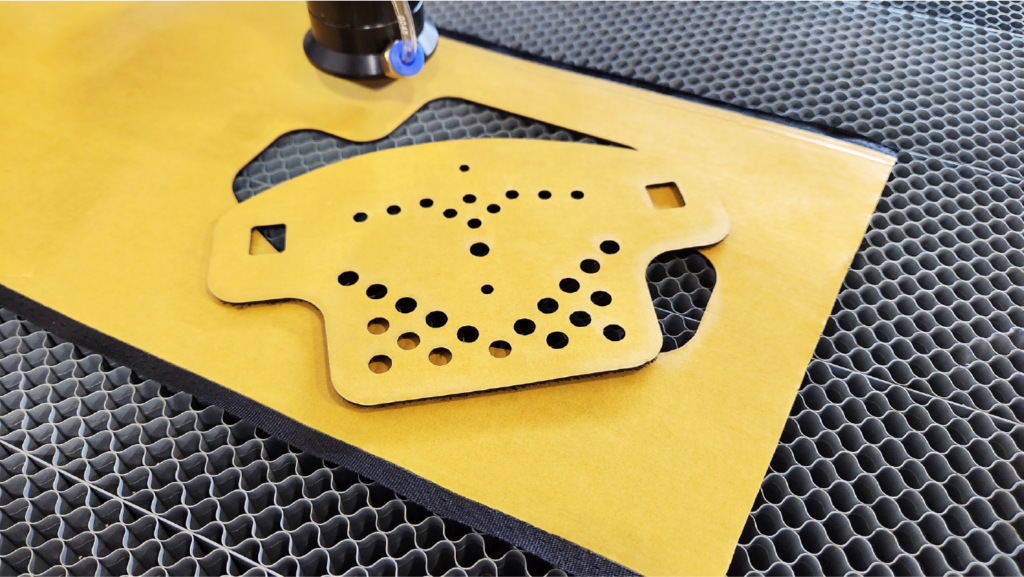

How It Works: Vacuum Precision Meets Laser Accuracy

The key to the laser cutter’s exceptional performance lies in its use of vacuum pressure to securely hold materials in place while the laser swiftly cuts through them. This method ensures that each die-cut part is produced with exacting precision, reducing material waste and increasing the overall efficiency of the cutting process. Before any of this happens, we work closely with a customer to finalize a part drawing that feeds the programming of the laser.

Why This Matters to You

By integrating this advanced laser cutting technology into our suite of converting services, Halco is better positioned to partner with you at every stage of your product development process. From the discovery and design phases through to prototyping, production, and beyond, our new capabilities will help you bring innovative products to market faster and with greater confidence.

Our dedicated sales and technical representatives are here to collaborate with you, leveraging our expertise in flexible closure and attachment systems to deliver tailored solutions that meet your unique needs. Whether you’re developing products that require specialty hook and loop materials, pressure-sensitive adhesives, or complex assemblies involving webbing, foam, or elastic, our laser cutter is a powerful new tool in our arsenal to ensure your success.

Get in Touch

If you’re interested in learning more about how our new large format laser cutter can support your projects, or if you’d like to discuss your specific requirements with our team, we invite you to reach out to us directly. We look forward to continuing our partnership with you and exploring the exciting possibilities this new technology brings.

Tell us more about your project and any need you might have for a laser cut prototype or large format die-cut. We partner with you at each step of the product development process.

.