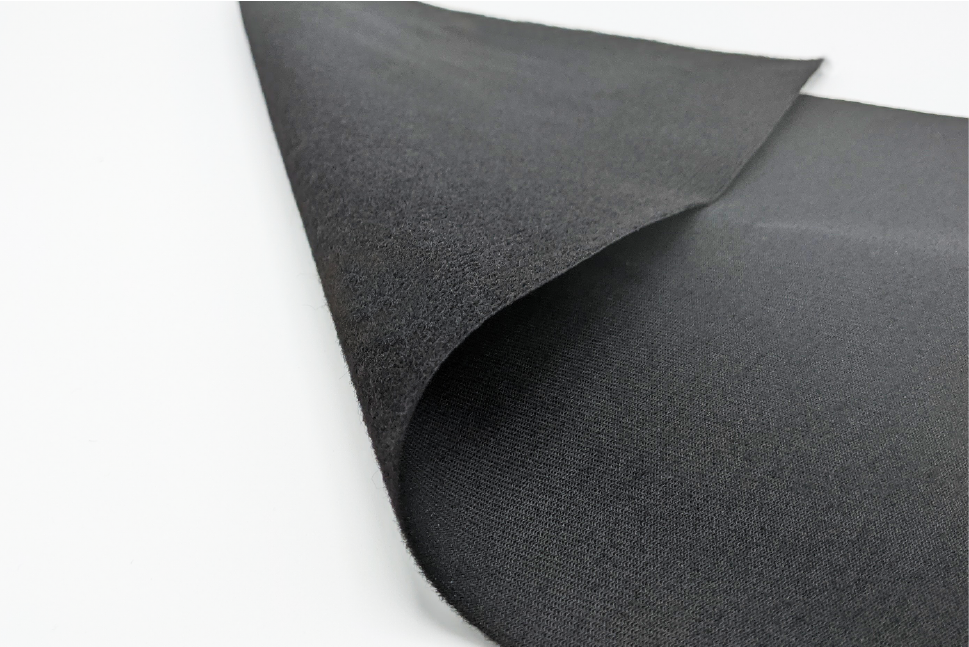

Most hook and loop products are relatively narrow and come in a tape format, with or without an adhesive. Halco’s wide loop is a specialty product different from these other hook and loop tapes. It’s a soft, flexible fabric in a wide format used in conjunction with hook fasteners. It is frequently adhered or welded to a backing material, such as a polyurethane foam or a backing material to provide a soft, comfortable closure system that meets your fastening system requirements.

Halco Helps You Design the Closure System’s Performance

What sets Halco apart from other suppliers of wide loop fabric is that we also offer a wide range of hook products that work with these loop fabrics. This means we are uniquely positioned to help an engineer design a fastening solution that meets their specific needs for:

- Peel strength

- Shear strength

- Cycle life

- Skin contact and other requirements

Halco offers a range of wide knit loop and wide woven loop fabrics with different characteristics. Some are thinner, others thicker. Some offer a tight loop for higher closure strength, others a looser loop. Closure systems with hook/loop combinations that have high peal and shear strength typically have lower cycle life whereas looser hook/loop combinations offer higher cycle life performance. Talk to a Halco representative to select the most optimal wide loop and hook products for your closure system design.

Halco stocks a variety of these fabrics, including a wide loop material for use in many military applications (holsters and belts, bags, pouches, helmets and vests) that is coyote brown.

Halco speed, flexibility and low minimums make the difference

Halco is known for its custom manufacturing capabilities, speed, flexibility and ability to work effectively on smaller and medium-sized projects with its customers.

Custom color program. For our wide loop fabric, we offer a dye-to-match custom color program with low minimums. This means that you can get a wide loop fabric that perfectly matches the color specs of your product for less than a thousand dollars.

Lamination to foam and other backing materials. Many customers who regularly use wide loop fabrics and foam have existing processes, like flame lamination, for adhering the two materials. Halco offers an adhesive-based lamination process for those customers who may want a wide loop fabric adhered to a foam or other backing material.

Talk to one of our representatives if you need a custom color or lamination to another material (like a polyurethan foam). We do this on a regular basis for many of our customers.

Common Applications for Wide Loop Fabrics

Halco wide width knit loop and wide width woven loop fabrics are commonly used in various applications, including but not limited to:

- Military gear and professional workwear: It is often utilized in clothing items such as uniforms, helmets, vests, holsters and other tactical products. The loop material provides a reliable and adjustable fastening method, allowing for easy and secure closure.

- Medical and healthcare: Wide loop is employed in medical braces, orthopedic devices, and compression garments. It enables medical professionals to create snug and customizable fits for patients, ensuring proper support and comfort.

- Industrial and safety equipment: Many industrial products and safety equipment incorporate wide width loop for fastening purposes. This includes items like straps, harnesses, tool belts, and protective gear. The loop material offers a secure closure system that can withstand demanding conditions.

- Automotive and transportation: Wide width loop is utilized in automotive interiors, seat covers, and cargo organizers. It allows for convenient and adjustable fastening, making it easier to secure items and maintain an organized space within vehicles.

Request a Sample / Talk to Us!

Do you have a project that uses wide loop? Tell us a little more about your project and request a sample for evaluation!